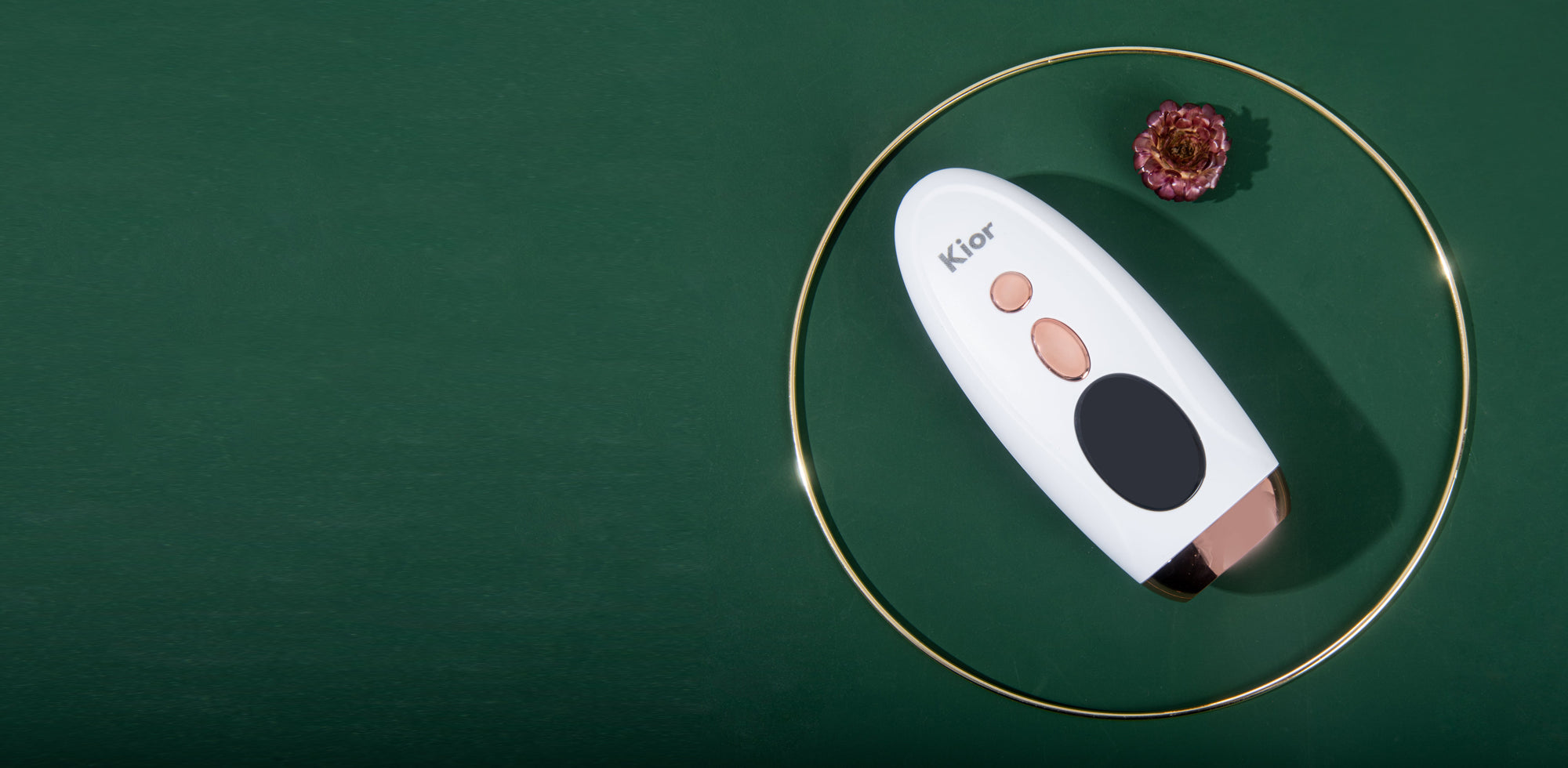

Acne and hair loss can be painful

Acne and hair loss can cause physical discomfort, affect mental health and self-esteem. The Kior Ozone High-Frequency Device addresses various skin concerns such acne, wrinkles and hair loss.

Achieve Glowing Skin

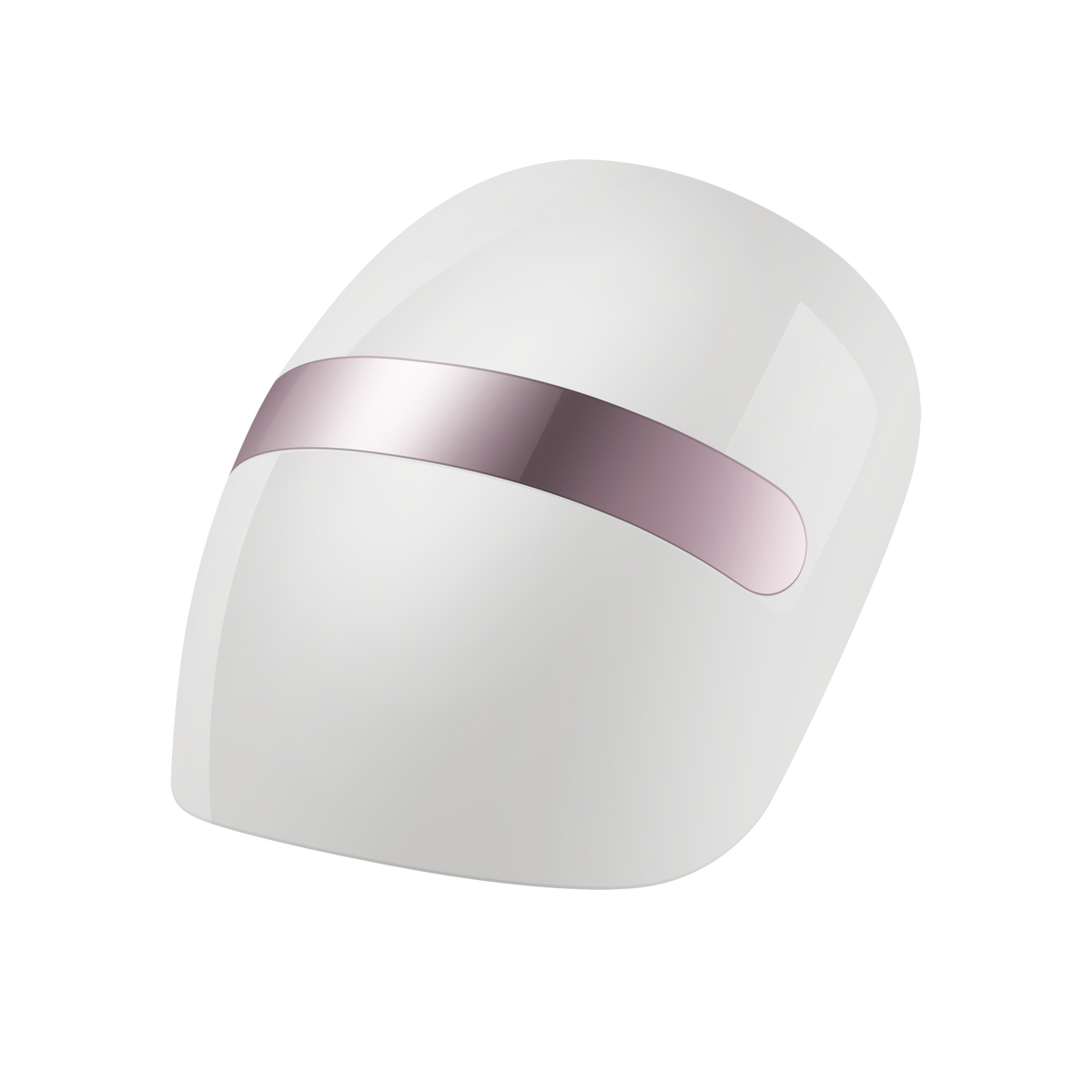

LED Mask

For acne treatment and other skin conditions, the Light Therapy Mask is the ultimate device for photo facial skin care.

We all know how much it hurts

"I don't always cut my legs shaving, but when I do it bleeds like a botched amputation"

Our IPL laser hair removal machine can safely and permanently remove hair. It emits a light that is absorbed by the pigment (melanin) in the hair. The light energy is converted to heat, which impairs the hair follicles that produce hairs.

Tested over thousands of sessions

No more messy breast feeding

Breast pumping can be painful and time consuming. But not with Kior Handsfree BreastPump. The FDA cleared device is easy to carry, light weight and quiet. Additionally,our breast pumps' each component can be flexibly assembled and disassembled.

As Seen On